The creation of an innovative package for a Micro-Electrical-Mechanical device

Client

A leading Microelectronics Manufacturer

Challenge

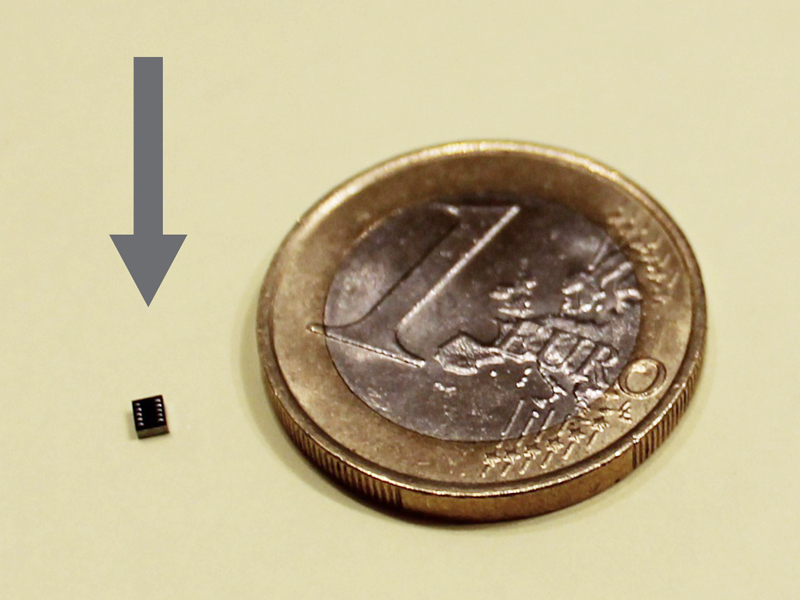

Led a team of engineers involved in an ENIAC (Electronic Numerical Integrator And Computer) EU-funded project. The brief was to design and prototype the production of an innovative package for a Micro-Electrical-Mechanical device that had no metal frame and would fit in 1.4×1.6×0.5 mm.

The Approach

The key to delivering this project was in understanding the fundamental challenges, both in human and technical potential, of the resources at hand. We adopted a structured approach towards dealing with the limitations and designed the device around these constraints.

Suppliers of equipment and materials were brought in to understand what current and new solutions could be applied.

The final design made use of new technologies to mould, build the internal contacts and provide the external contacts.

The Result

The final device satisfied all the criteria in terms of dimension and purpose. The novel external contact design, done without metal, allowed for a very flexible contact pattern, thus making the package suitable for various purposes.

The equipment and technology selected enabled the set-up of a pilot production line, which produced 100,000 parts. These were then tested, giving a 99.9% yield.

The project was reviewed by EU auditors and won the best ENIAC project in Europe in 2016.